We house the necessary measurement tools to ensure our optic solutions meets your requirements, and improve our internal processes.

Spectrophometry

Measuring Optical performance (reflection, transmission) in different AOI (Angle of Incident)

- Perkin Elmer Lamda 1050

- Perkin Elmer Lamda 850

Interferometer

Measuring surface flatness (PV,power,roughness)in both reflected and transmitted wave @ 632.8nm

Optical Centration Measurement

Measuring EFL,BFL,FFL, centering error

- Trioptics OptiCentric® with Opti Spheric Upgrade

Vision Measurement Machine

Our quick vision enables us to measure various optic component with accuracy,precision and speed.

- Mitutoyo Quick Vision ELF

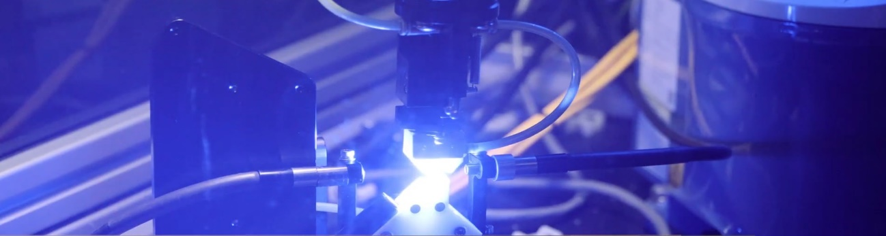

Microscope

Capturing images for failure analysis up to x 500 magnitude.

Handheld Equipment

- Mitutoyo Verneir Caliper (up to 300mm)

- Mitutoyo Micrometer (up to 75mm)

- Mitutoyo Digimatic indicator (Up to 12.5mm)

Visual Inspection

The team are trained in both MIL – PRF – 13830B & ISO 10110 cosmetic standards and have the necessary tools to inspect for Scratch & Dig and other cosmetics defects that can effect Optic performances. Our Inspection set up follows according to best practices & international standards, coupled with our know how in inspection lighting conditions, we detect defects to ensure only good parts are processed and delivered.

Competency

We follow strict calibration procedures and our metrologist is trained in measurement system analysis. We are able to conduct attribute agreement analysis, Gauge R&R studies and to ensure our Optics Solutions are delivered with precision and accuracy, and enables us to improve our process capability.